In the introductory post of this two part series I highlighted the finished product of my collaboration with Graham Withers and, as promised, in part two we'll take a look into the tie making process.

The ties being sold at

Graham Withers are hand crafted in NYC by a legend of the tie making circuit who's been in the industry for 40 years and makes ties for the likes of Thom Browne. He's such a secret weapon that when asked to reveal his identity, Paul would only disclose that the craftsman operates out of Chelsea. He hand stitches everything save the slip stitch - that runs the length of the back of a tie - which is sewn by a

Liba machine, (Paul adds "the quality of the Liba machine stitch vs handmade slip stitch is negligible).

|

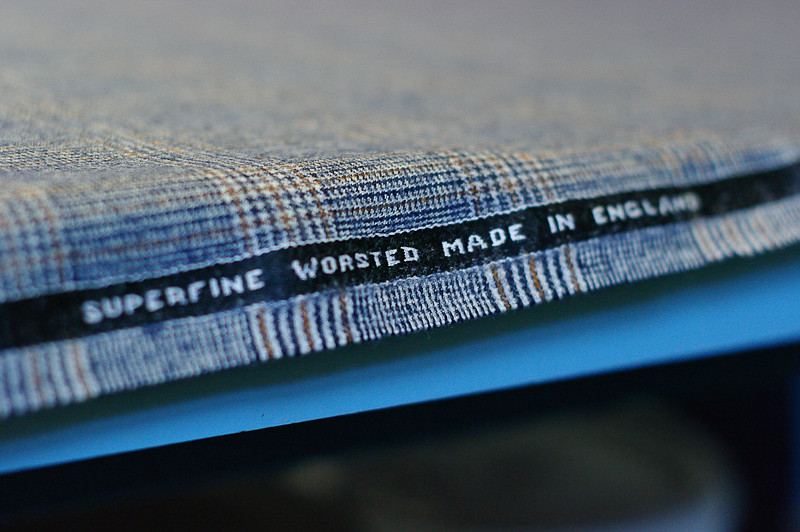

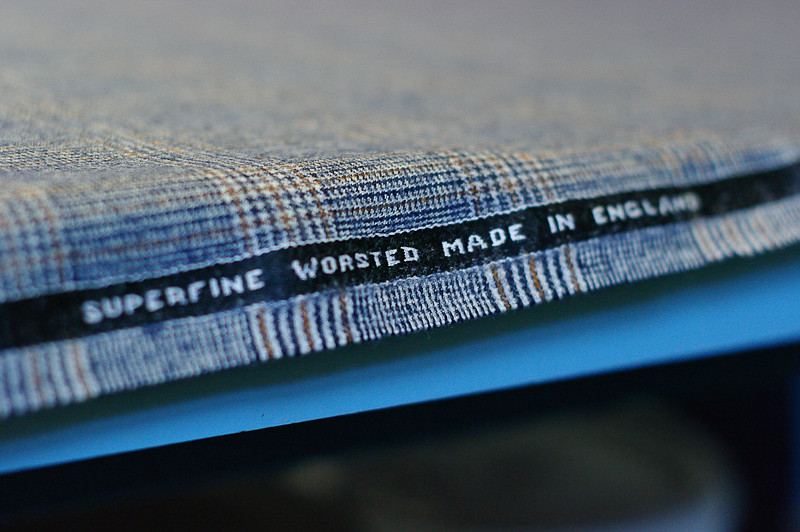

| The fabric: a worsted English wool tartan in a deep navy and russet stripe. The tipping is 100% cashmere |

Before Paul and Dave handed over manufacturing to their best kept secret, they handmade everything themselves at the factory that is the home base for Paul's family business in Long Island City.

They're entirely self taught and a few weeks ago, I rode out the factory with them to document their tag team process as they hand made

a Zupan tie from start to finish.

|

| Cutting the wool from the pattern. |

|

| Paul placing the tipping at the front end of the tie. |

|

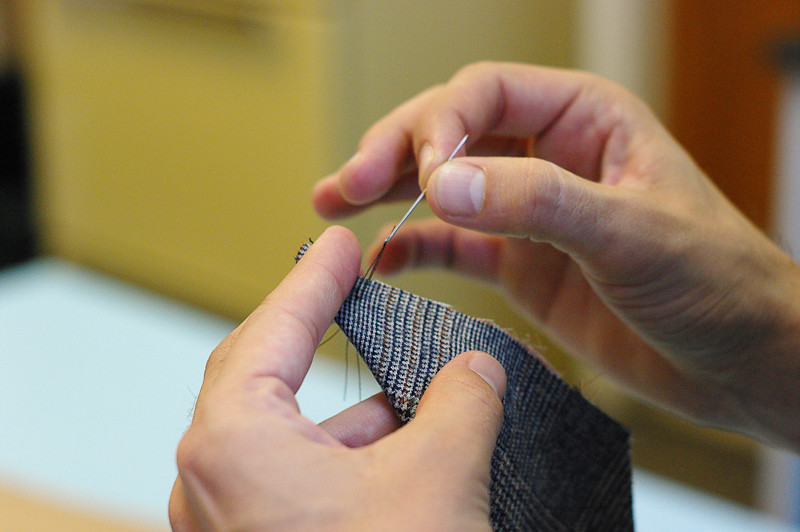

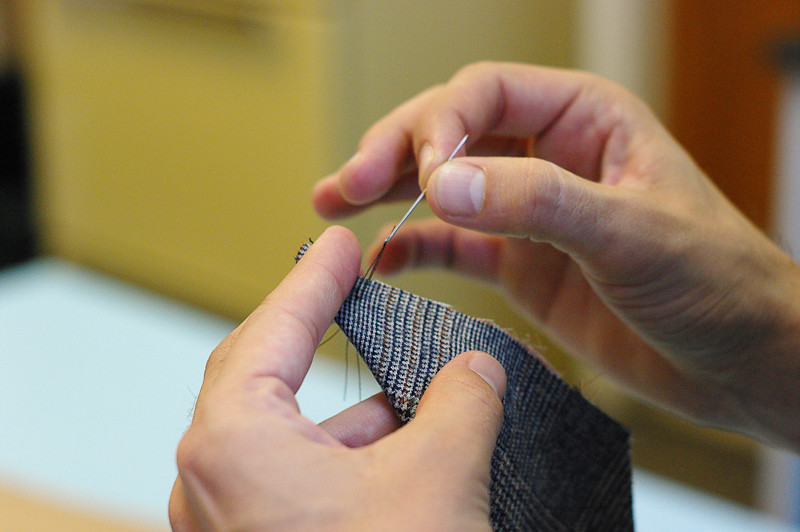

| Stitching the tipping in place |

|

| Paul sews the two ends of the tie together in the workshop at his family's factory |

|

| The sewing machine they use was once owned by a handy man who worked with the family business |

|

| The front and the back of the tie are joined |

|

| Sewing in the tipping |

|

| With the point complete, the tie begins to take shape. |

|

| Paul (seated) and Dave together in the workshop |

|

| Adding the core of the tie and folding the edges in. |

|

| The skinny end of the tie is pinned into place |

|

| The (nearly) finished product |

At this stage the slip stitch is hand sewn, which takes about an hour. The entire process took about two hours, and it was an incredible experience to watch these work together and this product come to life. See the full range of photos from the day

over at my Flickr. Huge thanks to both Paul and Dave for letting me be a fly on the wall while they work their magic. - M

Related Links